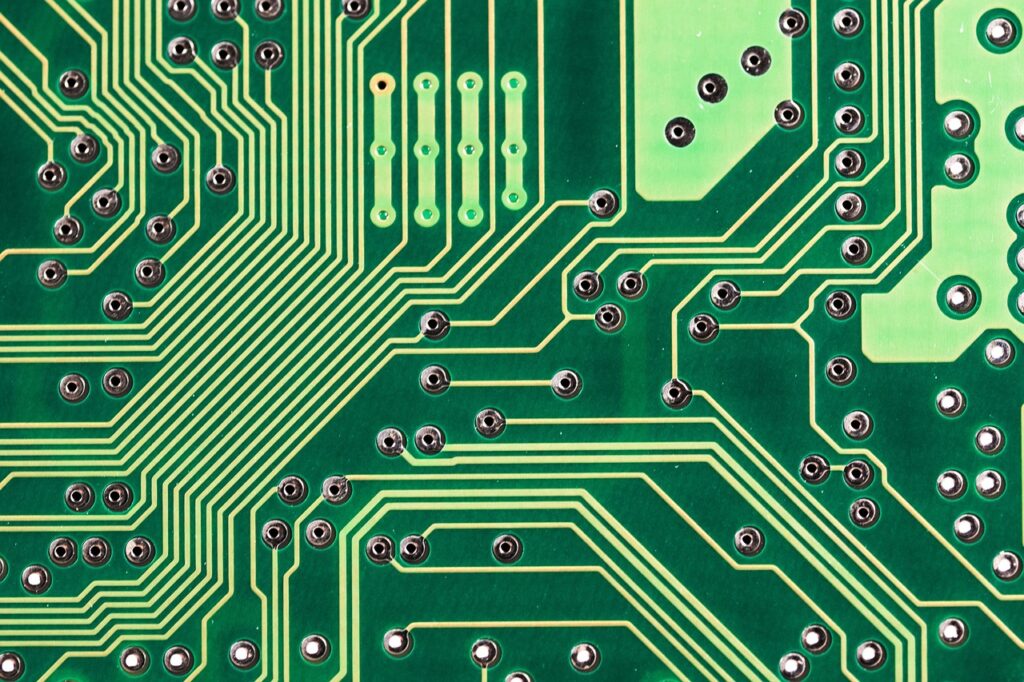

PCB is commonly known as “printed circuit board” It is a basic component in the electronics industry and serves as a platform to mechanically support and electrically connect electronic components.

PCBs are made of non-conductive materials, such as fiberglass, and have thin layers of conductor material (usually copper) in a specific pattern on their surface.

These conductor pathways allow the flow of electricity between components mounted on the board, making the operation of electronic devices possible.

PCBs come in different types which carries its complexity, including single-sided, double-sided, and multi-layered and its totally depending on the circuit design for the electronic device & applications.

PCBs are essential in everything from simple electronic gadgets to complex computing systems.

PCB is the major reason why electronic application & smart computing developed so quickly & now the future is going to be more and more faster than this where PCB is going to play a very crucial role.

Hand wiring: Hand wiring is expensive, time-consuming & there is lots of feasibility concern and application or design limitation.

PCBs give all the freedom which are not possible & feasible at all in hand wiring but also we can forget because still it exist where people & designer/developer use take help of hand wiring to understand & fulfil the design demand during the very initial stage of any new product design.

PCB

Printed Circuit Boards (PCBs): are essential components in modern electronics for several reasons.

- Electrical connectivity Support: PCBs provide a platform for connecting electronic components such as resistors, capacitors, inductors, IC’s, connector, switch etc. and integrated circuits. They facilitate the flow of electricity between these components through conductive pathways in a very accurate & controlled way.

- Mechanical support & feasibility: PCBs provide structural support for components, helping to securely hold them in place and protect them from physical damage & it can be design based on our requirement or design concept which products demands.

- Compact design concept: PCBs allow for compact and organized layouts, allowing designers to create smaller and more efficient electronic devices. This is important in today’s trend of consumer electronics.

- Ease of manufacturing process: PCBs can be mass-produced using hi-tech automated processes withing very short time with less efforts, in less manufacturing costs.

This help to meet the demands of consumer electronics like Cell phone, computers, electronic gadgets. - Thermal management: PCBs can be designed to manage the heat dissipation, which is critical to maintaining the performance and long life of user electronics.

- Great Reliability : PCBs are designed to be durable and reliable, able to withstand vibration, temperature changes, and other environmental factors which gives it a shape to grow in all the fields like- industrial, automation, public use & many more.

- Design flexibility: Engineers can design PCBs to accommodate different configurations, making them suitable for a wide range of applications, from simple circuits to complex systems.

PCBs concept for functionality and reliability of all electronic devices, start from smartphones to industrial automation, machinery, gadgets & telecom systems are very innovative.

Hidden Layers of Internets and Understanding the Dark Web